Electric Vehicle and Battery Testing

High voltage testing and measurement refer to measuring the electrical properties of a device or system that operates at high voltage levels, such as voltage, current, power, and insulation resistance, as well as other electrical parameters.

High voltage testing is important in designing, developing, and producing high-voltage equipment and systems, such as electric power transmission and distribution systems, high-voltage electric motors and generators, and high-voltage components for electric vehicles. The tests are done to ensure that the equipment can operate safely and reliably under the high voltage and power levels it will be exposed to in service.

Typical High-Voltage Test

There are several high-voltage tests, each with its specific purpose and method. Some examples include:

- AC dielectric tests measure the ability of a material or device to withstand high AC voltage without breaking down.

- DC dielectric tests measure the ability of a material or device to withstand high DC voltage without breaking down.

- Impulse voltage tests measure the ability of a material or device to withstand high-voltage transients, such as lightning strikes.

- Partial discharge tests measure the amount of electrical discharge within a material or device.

It is important to use proper techniques, personnel, and equipment when conducting these tests, as high voltage poses a serious risk of electric shock, injury, and death; For this reason, only qualified and trained engineers and technicians should be responsible for performing high-voltage tests.

What is EV and Battery Testing?

Electric vehicle (EV) and battery testing is the process of testing the performance, durability, and safety of the various components and systems of an electric vehicle, with a focus on the battery and its associated systems. This can include testing of the battery cells, modules, and packs, as well as the vehicle’s electric drivetrain, charging systems, and power electronics.

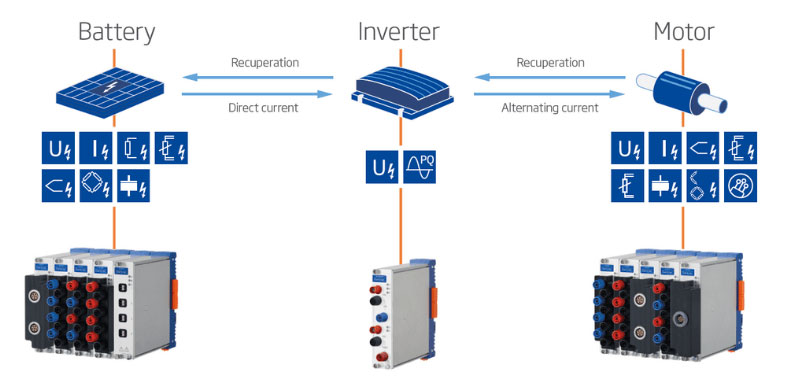

For all-electric vehicles (EVs) and hybrid electric vehicles (HEVs), a high-voltage bus, also known as the DC link, is a key component of the electric powertrain. It connects the battery pack, which stores the energy, to the inverter, which converts the DC power from the battery into AC power that drives the electric motor.

Most components are bidirectional, allowing for propulsion and regenerative braking. During propulsion, the inverter converts the DC power from the battery into AC power to drive the electric motor, which propels the vehicle forward. During regenerative braking, the electric motor acts as a generator, converting the vehicle’s kinetic energy into electrical energy that is then sent back through the inverter and used to charge the battery.

The goal of EV and battery testing is to ensure that the vehicle and its components meet the safety and performance standards set by industry organizations and governments, and to identify any areas where improvements can be made.

Where is High-Voltage Test & Measurement used?

Gantner Instruments provides High-Voltage Testing solutions for all battery development and qualification steps, including:

Charge/discharge cycle testing

Determine the number of times a battery can be used by evaluating it until it deteriorates after repeated charging and discharging charges.

Battery Model development

SoC, SoH determination and prediction, constant discharge testing, Charge/Discharge rate and efficiency

Safety (abuse) testing

Simulate a wide range of environmental conditions and battery failure scenarios to determine the conditions for battery failure.

Performance testing

Demonstrate the efficiency of batteries. Our experts can customize testing programs to suit specific customer requirements, such as performance testing under various climatic conditions.

Environmental and thermal testing

Demonstrate the quality and reliability of your battery. Our tests include vibration, shock, EMC, thermal cycling, corrosion, dust, salt, and humidity.

Transport testing

Ensure your batteries can be transported safely. We conduct tests for the United Nations requirements (UN 38.3) for the safe transportation of batteries, modules, and cells.

Impedance spectroscopy for Battery R&D and Production

Analyze capacity, cycling lifetime, shelf life, current carrying capacity, low-temp performance, and impedance of materials synchronously with other measurements, e.g., temp, strain gages, etc.