| |

|

|

|

| |

|

|

| |

ART logics provides testing module solutions for the Battery Management System Life

Time Testing (LTT) and End of Line Testing (EOL), pushing back many limits for testing

the battery cells pack!

|

|

| |

|

|

| |

|

LTT: the testing solution simulates the pack's battery cells operations

and fault simulations to verify the Battery Management System algorithm

has a coherent behavior at all time during the Life Time Test (LTT).

|

|

|

EOL: the testing solution simulates the pack's battery cells and other

signals from other ECUs around Battery Management System to active the

functions of battery Management System, then verify the Battery

Management System function and performance after assembly.

|

|

|

|

| |

|

|

| |

The BMS Test system Special Features

|

|

| |

|

|

| |

|

BMS: Life Time Test (LTT) with 6 units

tested

simultaneously

|

|

|

|

Simulation of the battery cells.

|

|

|

|

Simulation of the temperature sensors.

|

|

|

|

Simulation of the High-Voltages (800 V).

|

|

|

|

Simulation of the charge/discharge.

|

|

|

|

Simulation of the crash function (input

from ABS).

|

|

|

|

Simulation of the lock-during-charging

function (input from

actioner).

|

|

| |

|

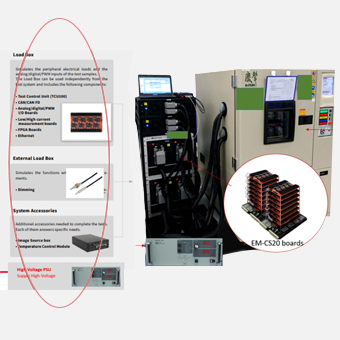

BMS: Life Time Testing System

Requirements

|

|

|

|

Check the Battery Management System

functions.

|

|

|

|

Check the cells monitoring.

|

|

|

|

Check the cells balancing.

|

|

|

|

Check the crash functions.

|

|

|

|

Representation of the test execution for EOL

testing

|

|

|

| |

|

|

| |

BMS: End of Line (EOL) Testing

|

|

| |

|

|

|

One test bench is composed of a moving box

containing power supply, loads,measurement

system, computer and peripherals. It is

placed on wheels and can be moved but cannot

be transported during tests.

|

|

Faster: There're fast exchangse to hold BMS

and exchange BMS easily and fast. The whole

test is implemented by embedded scripts that

shorten cycle time 10%.

|

|

|

|

|

|

|

| |

|

|

| |

BMS: End of Line Testing System Requirements

|

|

| |

|

|

|

To test BMS after assembly, verify all

functions of BMS. Input signals and

communication environment in vehicle to

drive BMS running. Manually/ Automatically

connect BMS and test all functions in a

short time. Generate test report.

|

|

|

|

|

|

| |

|

|

| |

|

ART logics system runs at the

customer

side

|

|

|

|

ART logics smart testing modules for

BMS

testing

|

|

|

|

|

| |

|

|

|

| |

|

|

| |

|

|

| |

About

Gopalam Embedded Systems

|

|

| |

|

|

| |

Gopalam Embedded Systems Pte Ltd

(GES) is an associate company of the ESA Group in India. GES,

together with the other ESA Group of companies, offers a wide range

of highly integrated hardware and software embedded solutions

ranging from - Development Suites, Middle-ware Solutions, In-Circuit

Debuggers/Emulators, Connectivity Solutions and Hardware Subsystems.

Through our ecosystem of tools and development solutions from

leading vendors across the world, we holistically support the

entire development life-cycle of embedded systems from design,

development, debugging to verification and validation.

|

|

| |

|

|

| |

All Rights Reserved © 2024 Gopalam Embedded Systems

|

|

| |

If you no

longer wish to receive these emailers, you may

unsubscribe

at any time.

|

|

|

|

|

|